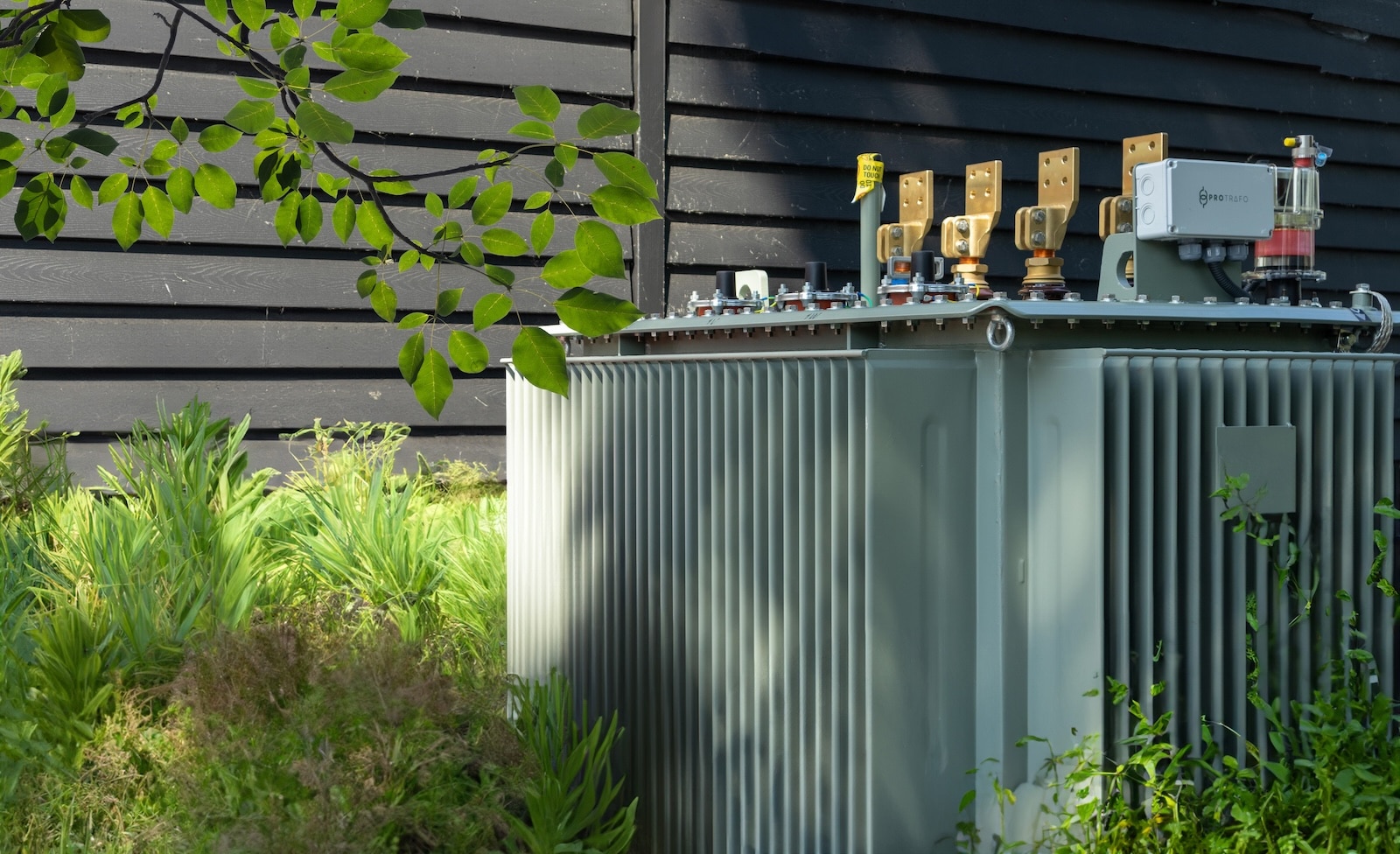

Protrafo's cast resin transformers

Exceptional quality and efficiency

Protrafo’s cast-resin transformers combine premium quality, safety and efficiency with excellent resistance to moisture, dust and temperature extremes. Their maintenance-free design and low energy losses ensure long-lasting, sustainable performance in a wide range of indoor and sensitive environments.

- Smart Monitoring Systems

- Our cast resin transformers can be equipped with intelligent monitoring solutions that track key parameters like temperature and load in real time — enabling predictive maintenance and improving operational safety across a range of environments.

- ECODESIGN Compliant Efficiency

- Designed to meet TIER2 ECODESIGN standards, our transformers are built for sustainability, offering exceptional energy efficiency with significantly reduced environmental impact.

- Moisture-Resistant Resin Insulation

- Each transformer is cast using high-quality epoxy resin under vacuum, eliminating air pockets and moisture. This ensures excellent insulation, dielectric strength, and long-term reliability in both dry and humid conditions.

- Silent and Efficient Operation

- Engineered for low sound emissions and minimal energy losses, our transformers are ideal for urban and noise-sensitive environments without compromising performance.

- Clean and Safe for Demanding Environments

- With no oil or flammable liquids, our cast resin transformers offer a fire-safe and environmentally friendly solution — ideal for indoor use in clean rooms, hospitals, and high-tech production facilities. Their dry-type design ensures safe, low-risk operation in environments where safety, hygiene, and reliability are essential.

- Safety-First Protection Features

- Advanced safety features — including temperature sensors, thermal protection systems, and self-extinguishing insulation — ensure safe and reliable operation, protecting both personnel and infrastructure.